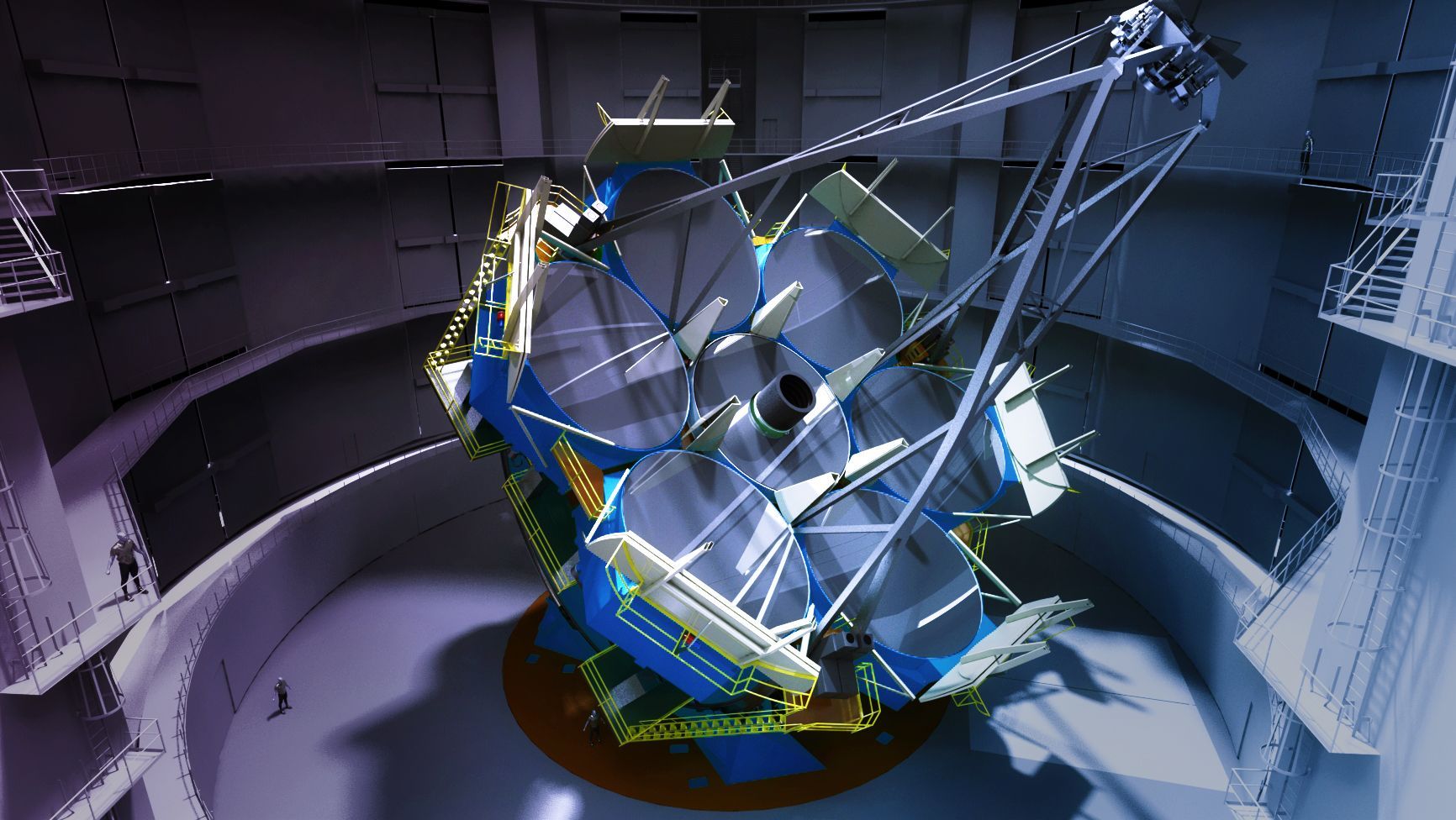

The Giant Magellan Telescope announces fabrication of the sixth of seven of the world’s largest monolithic mirrors. These mirrors will allow astronomers to see farther into the universe with more detail than any other optical telescope before. The sixth 8.4-meter (27.5 feet) mirror – about two storeys high when standing on edge – is being fabricated at the University of Arizona’s Richard F. Caris Mirror Lab and will take nearly four years to complete. The mirror casting is considered a marvel of modern engineering and is usually celebrated with a large in-person event with attendees from all over the world. Due to the coronavirus pandemic, work on the sixth mirror began behind closed doors to protect the health of the 10-person mirror casting team at the lab.

The peak temperature event is called “high fire” and will occur on March 6, 2021. The mirror then enters a one month annealing process where the glass is cooled while the furnace spins at a slower rate in order to remove internal stresses and toughen the glass. It takes another 1.5 months to cool to room temperature. This “spin cast” process gives the mirror surface its special parabolic shape. Once cooled, the mirror will be polished for two years before reaching an optical surface precision of less than one thousandth of the width of a human hair or five times smaller than a single coronavirus particle.